ISO 9001 Factory Powdered Nitrile Butadiene Rubber(PNBR-03) For Friction Material CAS NO.9003-18-3

- FOB Price: USD: 3,200.00-3,300.00 /Metric Ton Get Latest Price

- Min.Order: 1 Metric Ton

- Payment Terms: L/C,T/T,

- Available Specifications:

Standard(8.4-16.8)Metric TonStandard(1-8.4)Metric Ton

- Product Details

Keywords

- Powdered Nitrile Butadiene Rubber

- PNBR

- Powdered NBR

Quick Details

- ProName: ISO 9001 Factory Powdered Nitrile Buta...

- CasNo: 9003-18-3

- Molecular Formula: C21H27N3X2

- Appearance: White or yellowish powder

- Application: It's used for friction material such a...

- DeliveryTime: 15 days after order confirmed

- PackAge: 20kg net weight/ctn, 42 ctns/pallet, 1...

- Port: Shanghai

- ProductionCapacity: 10 Metric Ton/Day

- Purity: 95%~99%

- Storage: It's recommended that in the original ...

- Transportation: by sea, by air for sample

- LimitNum: 1 Metric Ton

- Mooney Viscosity: 100~150

- Bound Acrylonitrile: 35~40%

- Gel Content: ≥90%

- Volatileness: ≤1.0%

- Sieving Rate: ≥98%

- Mesh Size: 40 mesh, 80 mesh, 100 mesh

Superiority

Advantages

Powdered Nitrile Butadiene Rubber(PNBR) has good bonding effect,can increase the adhesive ability of friction material system.It can improve the impact strength of pressure embryo,and provide product flexibility.So PNBR is the ideal friction material modifier,mainly used for brake pad,train brake shoe,motorcycle and other fields.The main function and effect as following:

1.Modify phenolic resin,increase its flexibility and improve the frictional properties,thereby obtain high and stable coefficient of friction.

2.Add powdered NBR in friction materials can make rubber powder particles uniformly distributed in the mixed materials,thereby reduce the abrasion of the friction material.

3.Powdered NBR has good toughening effect as the elastomer,can increase the impact strength of friction materials.

4.PNBR can reduce products hardness and braking noise to improve braking comfort.

Details

Product Specifications

|

Index name |

Appearance |

Mooney Viscosity |

Bound Acrylonitrile |

Gel Content |

Volatile |

Sieving Rate |

Main field application |

|

Measurement Unit |

— |

ML100℃1+4 |

% |

% |

% |

% |

|

|

Test Condition |

— |

— |

— |

— |

105±5℃ 120min |

Standard380μm Top-grade180μm Special-grade150μm |

|

|

PNBR-03 |

White or yellowish powder |

100~150 |

35~40 |

≥90 |

≤1.0 |

≥98 |

Disk, drum brake pad, Clutch heading, grinding wheel, Abrasives, Train brake shoe and so on |

|

PNBR-04 |

≥150 |

35~40 |

≥95 |

≤1.0 |

≥98 |

||

|

PNBR-05 |

50~100 |

30~35 |

≥80 |

≤1.0 |

≥98 |

Applications

PNBR for friction material is used for disk,drum brake pad,clutch heading,grinding wheel,abrasives,train brake shoe and so on.

Packing

Cardboard box packing with PE liner on pallet, way of packing as below.

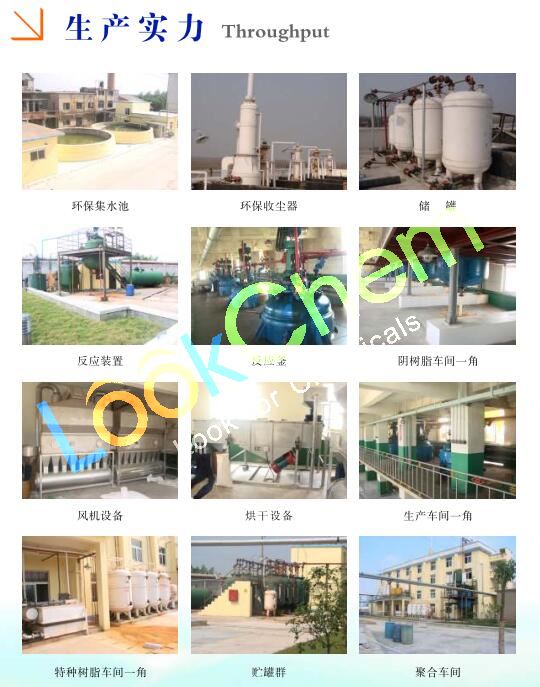

Company Profile

Shengdong Technology Co.,Ltd. is found in 2008. The company is a technology-based enterprise specialized in researching, manufacture and sales of Powdered Rubber, Nitrile Latex and Styrene Butadiene Latex. And is the earliest company engaged in the R&D and production of special synthetic rubber in China, also the member unit of China friction sealing material association. Shengdong Technology Co.,Ltd. belongs to Anhui Wandong Chemical Co., Ltd. , which was formally known as Anhui Wandong Chemical Plant. Wandong is a middle-scale chemical corporation founded in the middle of 1960’s, located in Tianchang City, Anhui Province. In 2007, Jianghuai (industrial) group acquired Wandong chemical plant. Anhui Wandong Chemical Co., Ltd. is one of the large-scale ion exchange resin manufacturers in China, as well as the deputy chairman enterprise of China Ion Exchange Resin Trade Board. In order to reduce the company’s operation costs, Shengdong Technology Co.,Ltd. and Anhui Wandong Chemical Co., Ltd. are merged in 2015. Wandong operates the manufacture of Powdered Nitrile Butadiene Rubber and Ion exchange resin, and Shengdong operates the exportation.